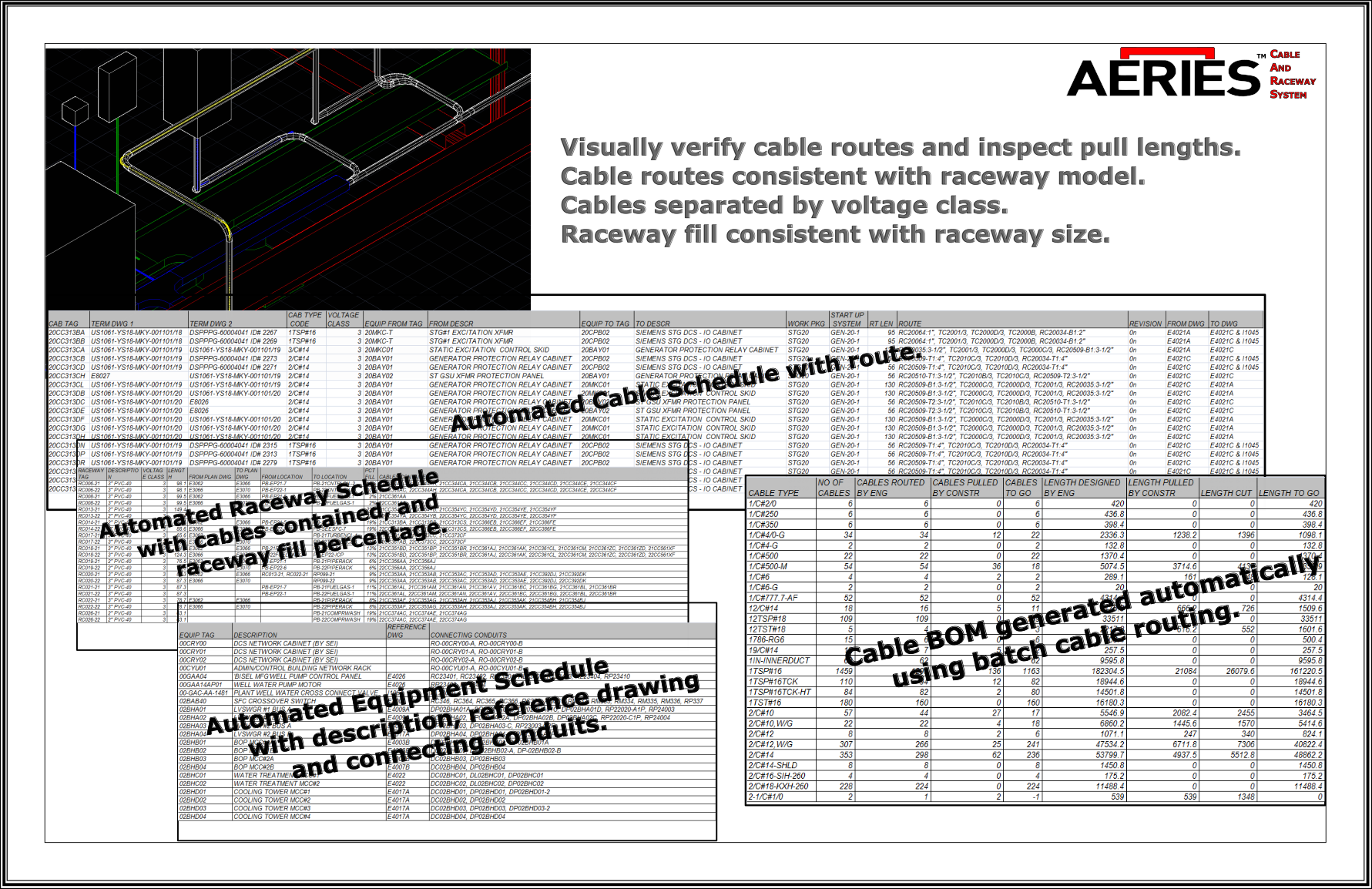

Automatic Cable Scheduling and Cable Routing

The spreadsheet methods built into the software are designed to maintain a connection directly to your database. The electrical designer or electrical engineer will prepare the cable schedule using the expected information:

Automatic Cable Routing Requirements:

- An origin and destination equipment...

- A voltage level...

- A cable type...

- A cable identifier...

This information can be entered via load scheduling software and imported to CableMatic Plus, entered directly into the cable scheduling software, or imported from an external source. Each electrical design module of the Aeries Cable and Raceway System is designed to work independently and together, giving the user more flexibility to work with the tools built in, whether it be the whole suite, or only the cable routing software.

The automatic cable routing process built in uses NEC raceway fill restrictions to avoid overfilling the raceway and reports all fill errors to the user to be dealt with accordingly; fill reports can be generated graphically or in a spreadsheet format. Where necessary, for example when working on a project overseas, the user can override the expected raceway fill limits when pertaining to conduit fill percentages.

Creating Project Deliverables

Deliverables are created and issued to the construction team on a scheduled basis set by you; this can be daily, weekly, monthly, or whichever technique is required for the project. With data flowing in both directions, both from your electrical engineering team to construction management, and from your construction management team back to electrical engineering team, up-to-date information is kept on all sides!

The construction management team is made aware when engineering has made a change that affects installation, and the engineers are able to monitor the progress of installation in the field in order to schedule their work load accordingly. This real-time connection allows for a better view of the project from all sides, which reduces costly mistakes and re-work!